what to use as a heat source for an incubator

If you are ready to get together the incubator with your own hands, then the information is for yous. Nosotros will tell most the incubator device in articles devoted to this topic, where we will try to tell in particular all the nuances and secrets of its blueprint and structure.

And now let's focus on the heating element, which is worth installing in a makeshift incubator. Consider several types and talk most their pros and cons.

So, you can warm:

ane. Carbon fiber heating cord.

Widespread use: it can human action as heating pipes or beds, floor heating in the chicken coop, well, for a warm flooring at home.

When computing the length, you tin make a fault, and this can lead to sad consequences, up to a burn down.

Winding must be done carefully on non-conductive electricity elements (textolite, fluoroplastic, ceramics). The installation itself must be done carefully and then equally not to damage the braid.

Conclusion : With all the minor disadvantages, this type of heating element is one of the best on the market place. The main thing is to correctly calculate the length of the heating cable. For this, our website has a calculator and a table. And retrieve that you lot should not pump more than than 18 watts of power into 1 meter of a Chinese heating cord.

Optimum windings for incubators will be given in Appendix No. 2 at the end of the commodity.

2. Ten

It can exist damaged if damaged mechanically.

Fast heating.

Pre-known capacity - specified past the manufacturer.

It does non modify its resistance sharply and is considered a resistive load, i.eastward. it can be connected directly to the thermostat without fear that its relay volition fail.

Relatively simple installation and connectedness direct to the contacts of the thermostat.

Inertia is one of the "fat" minuses of this blazon of heating chemical element.

The desired size + power must exist sought and selected to fit your needs.

Heating directly depends on the voltage in the network, so information technology is appropriate to employ a stabilizer if the incubator is operated, for example, in a hamlet.

Conclusion: Pluses seem to be more than minuses. Notwithstanding, the first two primary disadvantages (the get-go ane can exist solved), cover almost all the advantages of this heater.

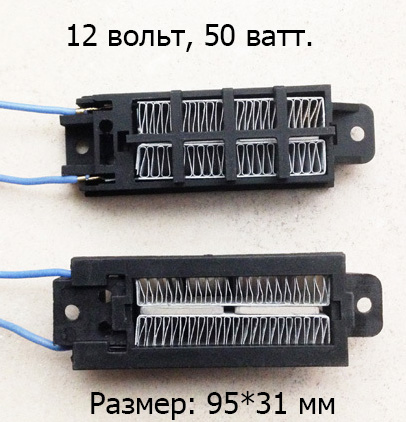

3. Nichrome wire

Connection is possible to 12 - 24 Volt DC or 220 Volt AC.

Fast heating - quick cooling.

Lack of inertia, due to this, a span in temperature is excluded.

The eternal heater, provided that the winding is correctly calculated depending on the supply voltage.

It does not change its resistance sharply and is considered a resistive load, i.e. it can exist connected straight to the thermostat without fright that its relay will fail.

Sometimes hard to notice in stores.

If yous make a error with the length of the winding and the supply voltage, it can lead to burnout of the wire.

Conclusion: If you programme to make a pocket-size incubator with the ability to work on battery, then this is one of the best decisions to make a heater for the incubator with your own easily. Optimum windings for incubators will be given in Appendix No. 1 at the end of the article.

4. Incandescent lamp

Fast heating, and lilliputian inertia

Low price.

Availability - can exist bought at whatever hardware or car store

Possibility of connection to 12 Volt DC - automobile lamps or to 220 Volt Air conditioning.

Simplicity of initial installation and replacement in case of failure.

The biggest minus of incandescent bulbs is that when you start in the first seconds, the resistance of the tungsten filament that is used in them changes dramatically. Because of this, a 25 Watt lamp can exist equated to a 250 Watt ten, and a spark slipping betwixt the contacts of the electromagnetic relay in the thermostat can very apace disable it. In that location is only 1 way to solve this problem - installing an intermediate solid state relay. We had several cases with improper connection as a result, the thermostat relay failed and this led to the death of the chicks due to overheating at the incubation phase.

Fragility

Decision: Quick, piece of cake, inexpensive, on the one hand. Not very durable, the nuances when using and connecting with another. And most importantly, later all, a light bulb is initially a light source and only then rut, therefore we do not recommend this type of heater.

5. Film for underfloor heating

Heats upwardly quickly and cools downwards

It has no inertia.

The film itself does not heat the air effectually it, since it has infrared radiation. Thus, the object in forepart of the picture is heated, in apartments it is a laminate or tile, and they, in turn, heat the air. Under the moving picture, it is necessary to lay a reflective substrate so that the heat does not go to the floor.

Connection merely to 220 Volt AC. If you lot want to power from the battery, you lot volition need to purchase an inverter, calculated past the power for your load.

Dear and not everywhere you lot can buy.

Very oft information technology is sold only with windings or sets together with a thermostat for a warm floor

It has a stock-still size (width) and power per ane sq. Thousand. (150 watts or 220 watts per 1 sq. M.)

6. Ceramic resistances (well, this is if there'due south aught more to estrus)

Conclusion:This blazon will not even be considered, and then it can be chosen the "ancient century" in the presence of other types of heaters on the market.

Then, the first thing to do is to immediately determine the supply voltage of our element, which will heat the incubator.

If you programme to make a small incubator with the power to switch to fill-in power from the battery and practise not program to buy an inverter, then your choice is a 12 volt heater, which can be made of nichrome, a heating cord or 12 volt car bulbs, provided that external relays are installed. When using nichrome or a heating cord every bit a heater, information technology is first necessary to make an accurate calculation of the length of the winding. Otherwise, if a mistake is fabricated, the heater can quickly fail. Power is selected depending on the size of the incubator, the number of eggs and the textile from which information technology is made. In all three cases, it is necessary to utilise a fan to remove heat from the heating chemical element.

In the event that you are not interested in connecting to the bombardment or if you lot plan to make a big incubator, then the heating element should be fabricated of a heating cable, heating element (consider power when choosing), nichrome or incandescent lamps of 220 volts, provided that an external relay is installed. When using nichrome or a heating string as a heater, information technology is beginning necessary to make an accurate calculation of the length of the winding. Otherwise, as in the instance of connecting to 12 volts DC, if an error is fabricated, the heater can quickly neglect. And remember that if a drawdown below 220 volts starts in the network, the incubator tin warm upwards poorly. If the incubator is built, more than than 200 eggs should accept care of buying a generator, since dead eggs can cost much more its price.

Below are the calculations indicating the power of the heating cord and nichrome, depending on the size of the incubator and the number of eggs. Much depends on the material from which the device is fabricated. Good thermal insulation of the sleeping accommodation means a stable internal temperature during incubation and lower electricity costs, since the heating element tin be gear up to the lowest possible power.

An incubator is an important apparatus for agronomical activities. It is with its help that young animals are hatched on an industrial scale. Likewise, many private entrepreneurs and only owners of small-scale farms are increasingly preferred to this method of hatching eggs over the natural, equally it is more than convenient and technologically avant-garde, and a higher outcome is guaranteed.

Although incubators operating on the mains have been used for several decades, existing models have several disadvantages. Heating and lamp apparatuses eat a lot of electricity, unevenly warm the air, create unnatural atmospheric condition for young animals, in that location is a risk of dangerous situations.

All these circumstances forced developers to seek new solutions. And not so long agone they appeared. The most promising and economical solution to date is infrared heating egg incubators.

The device and principle of operation of the infrared incubator

Different manufacturers of incubators reacted differently to the appearance of infrared heaters, so there are several models on the market. They take a similar design, but some differences are also present.

The structure of a typical infrared incubator

- Form gene: box with a chapeau.

- Material: forest, plastic, polystyrene foam.

- Capacity: 20-150 eggs.

- Power supply: 220 5, in some models it is possible to work on bombardment power.

- Automation: temperature controller, some models with a digital brandish.

- Some devices take the function of turning eggs.

- Operating temperatures: 0-100 degrees, the possibility of regulation in increments of 0.1-0.5 degrees.

- Microprocessor command.

Infrared Incubators tin can exist operated in a broad temperature range, but exclusively indoors. Optimum temperature environment: five-forty degrees. In this case, humidity should besides be maintained at a level of: 50-70%.

The principle of performance and capabilities of the infrared incubator

Modern infrared incubators are suitable for hatching the eggs of any birds and amphibians: ducks, chickens, geese, turkeys, ostriches, quails, parrots, turtles, snakes, geckos, iguanas, crocodiles and many others, if necessary. Working conditions are adjusted in accord with the requirements for the convenance of specific animals.

Chapters is limited solely by the size of the eggs. Some models provide for the possibility of seizing the mechanism that performs the rotation, in which case the rotation must be carried out manually.

Heating element in infrared incubator is a carbon pic heater. From the name it is obvious that heating occurs with the assistance of infrared rays, in this instance we are talking about the far spectrum.

An important feature of this applied science is that the heater itself has a temperature of no higher than 45 degrees while maintaining a standard mode of 35.v-38.v degrees for eggs. This is a definite advantage compared to heating elements and lamps, the temperature of which can attain 150 degrees.

Infrared incubator provides 100% survival for salubrious eggs, every bit information technology eliminates the very possibility of thermal shock, the near fatal for embryos and taking identify in the apparatus of a traditional device. Even a brusque circuit volition not damage hatched chicks or amphibians. Infrared rays warm the shell similar the dominicus, this heat is pleasant for living beings and has useful properties.

The presence of a temperature controller is a decisive gene. Infrared heating does not need human control, since information technology is done by a microprocessor, which receives information well-nigh the current temperature from the temperature sensor. It is possible to set degrees with loftier accuracy, and the system itself volition support them for the right fourth dimension.

The benefits of infrared heating for egg incubators

- This is the about natural style of hatching, after a hen. Modern applied science has many advantages.

- Full automation. The device for turning eggs performs its work with a given frequency, ensuring uniform heating from all sides.

- Optimum humidity. The problem of maintaining a specific humidity level has ceased to be. It is enough to place a container of water in the box. Fluid under the influence of infrared radiation evaporates at the same speed equally when heated by sunlight. It is plenty to add water as it evaporates.

- Natural ventilation. The housing has technological holes that provide optimal air exchange.

- Profitability. Infrared heaters eat a minimum amount of electricity, significantly less than lamps and heating elements, which reduces the cost of incubation at times.

Features of the operation of infrared incubators

Use of infrared incubators similar to the utilise of traditional lamp and X devices. They are friendly, as they are as automated as possible and do not crave increased attending to their own functioning.

It is enough to fill up the container with eggs and plug the power cord into a power outlet. All other actions are related to the incubation time and requirements for different breeds of birds and amphibians. The just matter to discover is the temperature and humidity in the room.

Egg incubator infrared heating - safe, affordable and economical solution!

Thermal cord (heating cable).

So the Chinese put the heating cord in the greenhouse. Cached directly in the ground and put on the floor for seedlings. Interestingly, a carrot that grows a fiddling faster pays for the costs of email. energy?

The extreme photo shows how the Chinese connect the thermal cord to a conventional wire and what tools and materials are used for this, I call back it'southward not necessary to explain, everything is clear from the photo. (Photograph clickable)

puddles for extensive heating of something. For case, it is successfully used in the installation of warm floors, heating bedspreads, rugs, etc.

The heating cord is very user-friendly for heating in the greenhouse, cords are produced specifically for heating the greenhouses (100 meters-ane kW. Ability) In general, for annihilation, because the cord is not afraid of excesses and moisture, it easily fits and cuts to the desired length.

Thermal cords with resistance from ten to 600 ohm / meter are produced. Based on this, information technology is easy to calculate the required length or power.

A very of import quality of the heating cable, it tin be powered by any voltage, literally from six-12 volts (recall the heated seats in the motorcar) to almost infinity. It is not permissible to just exceed the melting temperature of the string insulation.

The heating cords are produced in a thermo-moisture-resistant casing (outset photo) and without it (cheaper). The former are used anywhere, the latter for the production of various heating pads in places that practice non allow high humidity (rugs, rugs, machine seats, etc.)

The adding of power (length) is possible past the formula. Example: let's say nosotros have a supply voltage of 220 volts, a cord length of iii meters,

cord resistance is 76 ohms per meter. Consider this: 220x220 / 3x76ohm. \u003d 212 watts.

If with the same parameters the voltage is 127 volts: 127x127 / 3x76 \u003d 70.7 watts.

Or: Let's say ix meters of the cord, voltage 220 volts, cord resistance 142 ohms: 220x220 / 9x142 \u003d 38watt

That is, for 100 rubles you can make a good heating pad with power switching.

For a heart-searching box I use a cord with the simplest temperature controller, and so you tin smoothly adjust the temperature.

Non all thermal cords are released by meters, oft the Chinese do not desire to cut and tinker with trifles.

Less than l meters, the Chinese practise not allow get.

The price of the cord depends on the selected material (with a beat out or not) and on the length. For a string with a sheath, the price is 57 rubles per meter., On condition of purchase from 100 meters. Less than 100 meters, the price is 63 rubles per meter.

Or if you take a bay (400 meters, seen in the photo) and so the cost is 53 rubles per meter.

For a cord without a shell, the toll is 39 rubles per meter. Bay 32 rubles per meter.

The toll of a bay for greenhouses (third photograph) 1000W - 100m \u003d 3100 rubles.

There were sets, measuring segments of the cord for the manufacture of incubators.

10m 33ohm / meter \u003d 760 rubles, fifteen meters - 990 rubles, 20 meters - 1280 rubles.

Enquire for other sizes, not always there ....

Answers to some questions I received in the mail:

The thermal string can be cut as you like, for any number of meters you need. At the same time, you should adhere to the above calculation method.

The thermal cord can exist powered with virtually any supply voltage, including DC voltage.

The thermal cord tin exist immersed in h2o, this is not dangerous provided that there is no damage to the insulation.

The thermal string can exist glued to the surface with tape or silicone.

The heating cord during installation does not solder, the ends are sealed by crimping and protected by heat compress or electrical record.

The heating cable can be ruby, white, bluish of any color !!! Therefore, please do non ask how much the cherry-red thermal string costs.

Portable scales up to twoscore kg.

Portable scales up to twoscore kg.

Thermostat for greenhouses. (special for heat cable)

Specially designed for heating cablevision, a powerful two-channel thermostat for greenhouses and greenhouses.

Ability: v.5KW (resistive); iv.5kw (inductive), power consumption:<3 Вт

Cost: 2900 rubles.

Self-adjusting heating cable.

220volt, 17 W / meter, 9mm. width.

The principle of performance of a cocky-regulating heating cable is visible from the figures to a higher place. To put it but, then: The colder the heating object, it warms more than, warmer - on the contrary, less. Appropriately, the power consumption is reduced.

50 meters. Toll: 4700 rubles. 10 meters: 1540 rubles. At that place are other sizes, ask.

Infrared heaters.

The most platonic and stable rut source for all types of animals.

Standard base E-27 nether the CERAMIC cartridge.

Voltage 220 V. Power: 25 - 200 watts.

Ceramic infrared lamps belong to the dark ceramic infrared heaters with a standard base. They have various applications, in practise they are used in terrariums and rooms for animals, for breeding animals and plants, in medicine and in the service sector.

They are mainly used for local heating of any living creature from to a higher place. Infrared radiations is close to the solar spectrum, therefore information technology is proved that it has a very favorable result on living organisms. Chickens grow stronger.

Information technology is very convenient to use heaters swirling instead of an incandescent bulb; heaters with a ability of 25-200 watts are produced.

It is advisable to utilize them together with ceramic lampholders.

Price: 650 rubles. With delivery in Russia.

Three loftier-speed heat fan with backlight. For installation in brooder boxes for heating chickens-quail. Or to heat newborn piglets.

Dimensions: diameter thirteen.3 cm, meridian: 14 cm Weight: 400 chiliad

Power: iii adjustable modes - 100 W 200 Westward 300 W

LED lamp power: ane Due west

Price: 1100 rubles, with delivery.

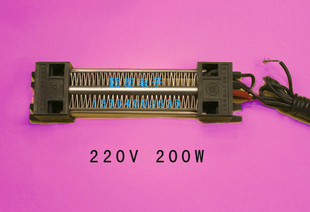

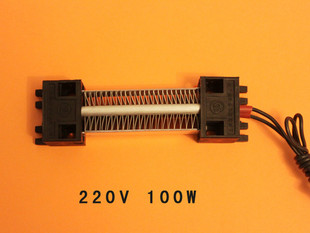

Air Tena.

Serve to heat the air in a homemade incubator.

Bachelor in various designs and capacities, a worthy alternative to incandescent lamps and dwelling house-made spirals in incubators.

The advantages of these tens are that they accept very good oestrus dissipation, and so they practice not overheat (of course, you must create sufficient air pressure level) and do not create thermal energy that is characteristic of tubular tens. It is very of import that a thermal relay is installed on each heating chemical element of 500 watts (run across the photo), at the slightest overheating information technology disables the heating element. Such relays tin be installed on any air heater.

In the photo at the height of the heater is 120x55x30 mm in size. ability of 500 watts. The cost is 1100 rubles.

Below, a heating element measuring 140x35x26 mm with a ability of 200 watts, without a thermal relay. The price is 920 rubles.

100 Watt Teng: 113 * 35 * 26mm. Without thermal relay. Price: 640 rubles.

P.S. Air Tenes are issued up to 4000 watts, ask.

For supply voltage: 12-380 volts.

Not all relays install these relays, but you tin install the relay yourself on whatsoever heater.

Not all relays install these relays, but you tin install the relay yourself on whatsoever heater.

As a rule, they are available with the post-obit shutdown temperatures: from 40 to 180 degrees (as normally airtight) The photo shows that the relay is 85 degrees off.

Relays are designed for currents upward to 5 A.

Cost: 130 rubles.

Incubator Kit: Air Ten & Fan.

- Voltage: 220 Volt

- Ability: 300 W

- Size: 125 * 80 * 92 mm

Price: 2900 rubles.

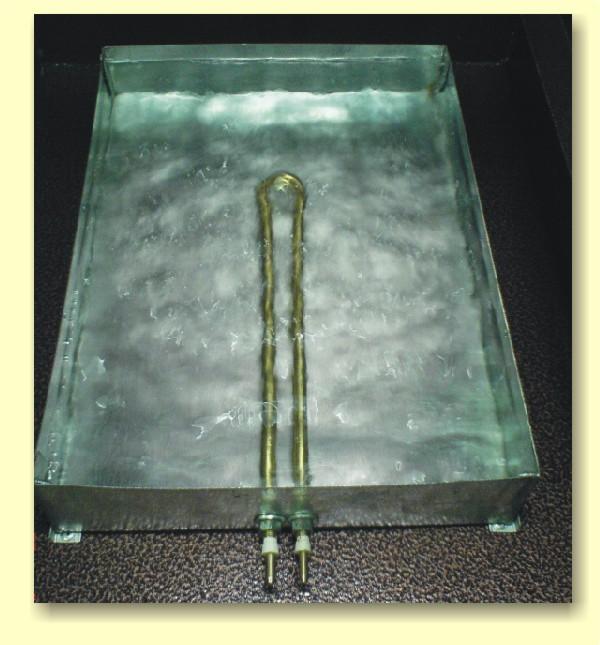

As one of the means to increase hydration during incubation, apply water heating in the bath.

For this, special depression-power heating elements are produced, with a capacity of 200-300 watts. Tena are made in such a way that they can be attached to the bath with water made of galvanized metallic through the special gasket included in the kit. The principle of performance is this, the device, when the humidity in the incubator is lowered, turns on the heater, the water is heated and water vapor flows from the fan, moisturize the air in the incubator. A big disadvantage of this method is that you must always look at the water level, otherwise the heater will fire out instantly, which entails the operation of traffic jams and a power outage. If there is nobody in the business firm, then the incubator elementarily stands upwardly.

10 power 200 watt, length: 200mm. 300 watts, length: 300mm.

Price: 200.- 600 rubles, 300.- 650 rubles.

As an choice to provide the necessary humidity in the incubator, you can install a h2o pump (ask) and supply water through it to a sponge, for instance. From a sponge h2o, under the influence of an air stream .... This scheme is often used in imported incubators.

Water electro valve for adjusting humidity in the incubator.

An easier option for adjusting humidity is to install an electric valve. The device works out, the valve turns on and water flows through the tube to the evaporator (sponge, material). The valve is released at: 12, 24, 220, 380 volts.

Price: 390 rubles. Temporarily non.

About ways to increase humidity in an incubator:

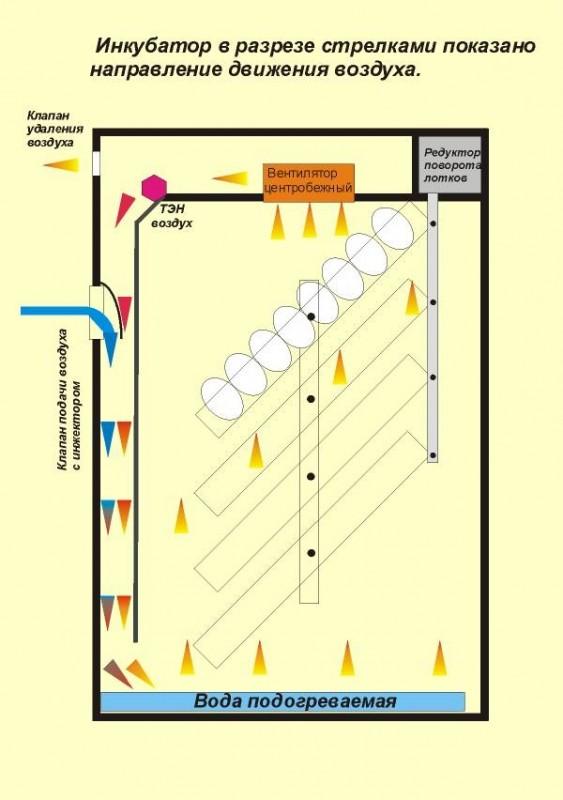

Centrifugal air blower for a homemade incubator.

Powerful centrifugal blower fan for a homemade incubator.

On the left is a homemade incubator scheme taken from an Net,

Here is an instance of the utilise of a supercharger.

Dimensions: 250 x 210 mm. productivity: 140 cubic / yard.

Supply voltage: 220 volts.

Price: 3100 rubles.

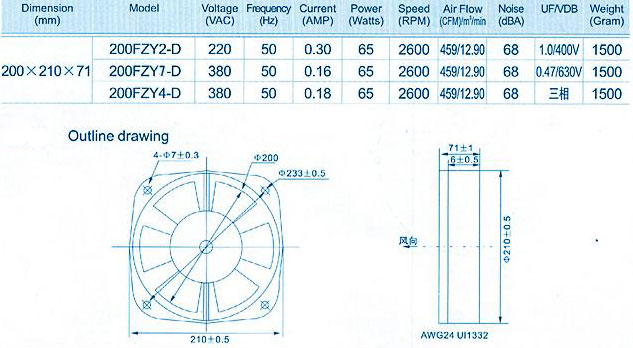

Powerful axial fan for a homemade incubator with a diameter of 200mm.

![]()

I call up based on the size and tabular array everything is clear ...

On bearings !!! Productivity: 280 cubic meters / hour.

Cost: 3900 rubles.

Centric fan for a homemade incubator with a diameter of 160mm.

The performance of this axial fan, at 220 volts: 1500 m3 / hour.

The description contains functioning data (airflow) for the supply voltage: 110 - 380 volts.

Price: 4900 rubles.

Price: 890 rubles.

Fans for ventilation of the incubator (100 - 150mm.) Ask, there are many of them ...

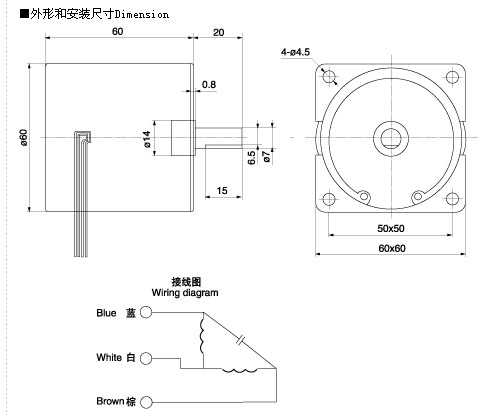

Fan for a homemade 12 volt incubator.

If desired, it is possible to choose a gear motor for the incubator for any need, a lot of options.

If desired, it is possible to choose a gear motor for the incubator for any need, a lot of options.

Toll: 2400 rubles.

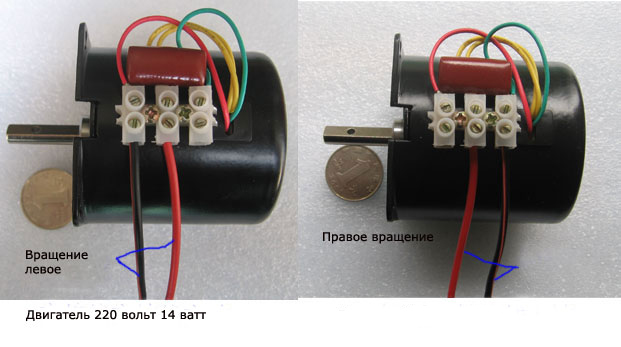

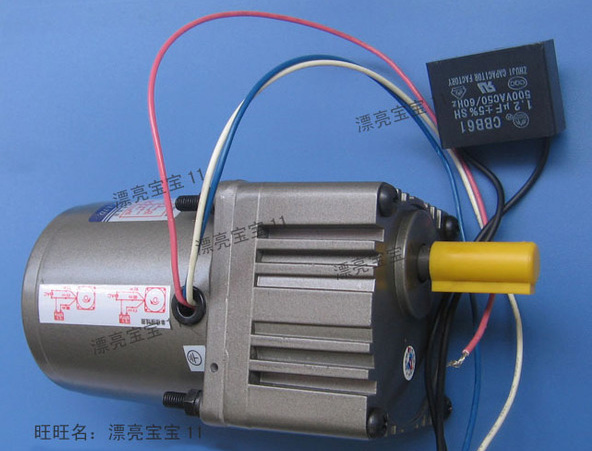

Reversible motor with gearbox for a dwelling-fabricated incubator for 220 volts / 14 watts.

The well-nigh popular (and reliable) correct at present is the reversible gear motor for incubators. It is produced for a different number of revolutions, respectively, and for unlike traction. Unlike the domestic RD-09 engine, these motors are powered by 220 volts, that is, they do not need a step-down transformer to achieve total ability. This serial of reversible motors for the incubator is the all-time suited for t. in it, and in all well-known industrial temperature controllers, admission to control the rotation of the trays by 220 volts. At the same time, the now fashionable actuators from satellite antennas are powered by a voltage of 36 volts. That is, they require a step-down transformer and complex relay isolation to switch the voltage. Definitely, these engines are the best choice when building a homemade incubator, because they work direct from the thermostat, and to change the rotation they demand simply the simplest limit switches.

- Engine ability 220V 50Hz, cylindrical gearbox, metal wheels.

- The operating mode of the reversible gear motor is continuous with the possibility of frequent starts and braking.

- Insulation resistance, not less than 100 MΩ at 500VDC

- Dielectric strength, in k for one infinitesimal

- Insulation Grade B (130º)

From the table it is clear that the less revolutions on the shaft, the greater the pulling force.

Engine cost: for 14 watts - one,500 rubles.

For some reason, limit switches are expensive, possibly considering they are designed for high current, only notwithstanding they control the engine

Left (10A. 250volt) - Price: 200 p. / Pcs. Right (5A. 250volt) - Price: 170 p. / Pcs.

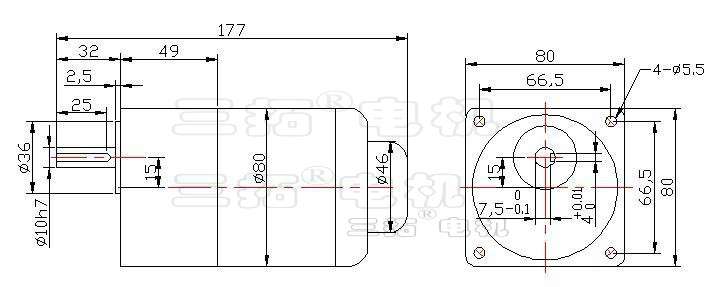

Motor for bulldoze trays in an incubator of 220 volts, 6 watts.

Reduction reversible motor to drive trays in the incubator.

Supply voltage: 220 volts. Power: 6 watts.

Bachelor in the number of revolutions: 1、2.5、five、8.3、xv、sixteen.7、20、25、thirty、35、40、50、60、lxxx、100、150 Accordingly, the smaller the number of revolutions, the greater the power on the shaft. Not all of class are available, ask.

Price: 1670 rubles.

Motor for drive trays in an incubator of 220 volts, 20 watts.

A more than "solid" engine to drive trays in a makeshift incubator. Reinforced gearbox of this engine, tin withstand trays with 1000 eggs.

Available at: five, xv, 24, 47 rpm. Bollard pull, respectively: 60, 50, 31, sixteen kg./cm.

Price: 6190 rubles.

The engine for driving trays in a large incubator for 220 volts, 25 watts.

Bearing units for tray drive machinery.

For any shaft diameter, ask.

Left row:

The inner diameter of the shaft is from four to thirty mm.

Toll: under a shaft of 8 mm. - 180 rubles.

Price: nether a shaft of 10 mm.-200 rubles.

under a shaft of 12 mm. - 230 rubles.

Correct row:

Cost: nether a shaft of 8 mm.-210 rubles.

Toll: under a shaft of 10 mm. - 240 rubles.

under a shaft of 12 mm. - 280 rubles.

A table of sizes of bearing bearings used in the drive tray of a makeshift incubator.

Hinges to drive trays in a makeshift incubator.

![]()

For what they are used, information technology tin can be seen from above in the photograph. Without them, the tray drive (of any design) will not work !!!

The sizes under an axis are from 5-sixteen mm.

Hinge price with a hole for the centrality-8mm .: 240 rubles. Ask for other sizes.

Device for controlling the speed of an Air conditioning motor.

It tin exist used to control the speed of the fan motor in the incubator.

Many are now asking where to get a low-revving engine for blowing trays in a makeshift incubator. I honestly practice not know, you can certainly utilise reduction engines (they are higher), but yous can employ this device. If a fan is installed on the motor axis, for instance, from a washing automobile and powered through this device, information technology will be possible to adjust the engine speed from 150 to 1390 rpm. It turns out the ideal fan for bravado trays in a bootleg incubator.

There are ii types of regulator, with and without indicator.

The price of the device with an indicator: 2400 rubles Without an indicator: 1800 rubles.

In recent years, in agriculture, hatcheries are widely used to remove young animals. The employ of incubators has been shown to be highly effective both for large agricultural enterprises and for small households.

As a dominion, incubators with electric heating are used. Among electric incubators, the well-nigh advanced are incubators with infrared heating. Such incubators accept several advantages compared to other types of electric incubators (lamp and heating elements). First of all, heating using infrared radiations provides a significant reduction in energy costs. Free energy savings are accomplished due to the fact that the thermal free energy from infrared emitters is transferred directly to heated objects (in this instance, eggs), and the air in the incubator is heated already from heated eggs. Another advantage of using the infrared heating method in incubators is the ability to control the temperature in the incubator and the long life of the emitter itself. In addition, due to the wide selection of infrared emitters, it is usually possible to choose the emitter module that is best suited for a particular incubator.

An example of an infrared emitter is the ECZ infrared lamp with an E27 screw cap. normally screwed into a special ceramic lampholder - similar to the i used for conventional incandescent bulbs. Due to the resistance of ceramics to the influence of high temperatures, such cartridges do not dry out and do not cook during operation, as is the case with plastic cartridges.

An example of an infrared emitter is the ECZ infrared lamp with an E27 screw cap. normally screwed into a special ceramic lampholder - similar to the i used for conventional incandescent bulbs. Due to the resistance of ceramics to the influence of high temperatures, such cartridges do not dry out and do not cook during operation, as is the case with plastic cartridges.

Infrared emitters are usually installed at the top of the incubator bedchamber - so as to ensure compatible heating of the surface on which the eggs are located. Depending on the size of the incubator, the number of emitters may exist different. Infrared heated incubators are fully automated: with a given frequency, the surface with the eggs rotates in lodge to ensure their uniform heating from unlike directions.

The problem of maintaining the necessary humidity in the incubator is solved simply - a container of h2o is placed inside the incubator, which evaporates under the influence of infrared rays.

Infrared heaters - This is one of the types of infrared heaters that are often used to rut industrial and domestic premises. IR heaters are made on the ground of ceramic infrared emitters, therefore they exercise not glow, take great mechanical strength and are absolutely condom. The main advantage of such heaters is the ability to create different temperature zones in one room.

The emitter of the ECZ and ECX series is made in the form of an electric bulb (spiral cap E27) with an air absorber inside the housing. Maximum surface temperature

Many summer residents and owners of private households decide to engage in poultry farming. There tin be a lot of motives for such ideas. This is an additional income from the sale of chicks or adult poultry meat, and purely artful pleasure, and the desire to eat environmentally friendly meat and eggs. Therefore, later in this commodity we will describe in detail how to organize incubator heating: types, methods and features of piece of work.

Destination

Accept a closer look at the following photo. Here is an incubator. Such equipment is used by farmers to regularly breed offspring of poultry. It allows you lot to get chicks exactly at the moment when it is necessary for a person and in the corporeality that he needs.

However, in fairness, we annotation that a hatchery volition be successful merely if the owner of the household will strictly follow all the rules for the removal of chicks using such equipment. Violation of the lighting regime, temperature or humidity level tin lead to the death of the embryos in the eggs.

That is why information technology is so important plenty to know exactly how to arrange incubator heating with your own hands and what yous demand to get for this (underfloor heating panels, infrared moving picture, LEDs, heating elements, fan heater, hydrocarbon wire, etc.). Later on all, each of the higher up methods is characterized by certain disadvantages and advantages, by comparing which you can understand which of this is nearly efficient and unproblematic to organize yourself.

What is the most successful heating method?

In fact, there is no clear reply to this question. Feedback from farmers suggests that much in this affair depends on the specific atmospheric condition of incubation. And, including, from the experience of the farmer in this matter. All the same, further we still effort to find the reply to the question of which heating is better for the incubator.

We use incandescent lamps

Often a person decides to follow the simplest, at kickoff glance, path, and organizes the next incubator heating: an incandescent lamp is installed inside the unit, the heat from which heats the eggs in the trays. The light sources must exist placed at the correct distance and then that the heat from them is evenly distributed throughout the space inside the incubator. On boilerplate, they are mounted at a altitude of ten cm from each other.

However, this method, according to experienced farmers, is complicated past the fact that in that location is a risk of rapid combustion of lamps, as in the case of heating the unit from the inside by heating elements. Often this leads to the melting of the walls of the unit of measurement, and in rare cases, the legs can even explode, which negatively affects the condition of time to come chicks. In addition, this pick is non and then depression cost, considering now electricity is non a cheap pleasure.

Underfloor Technology

If you decide to do the incubator heating with underfloor heating panels with your ain hands, and then y'all should understand that such a method of thermoregulation within the equipment can cost decent money. Moreover, the choice of such heating elements is not then loftier.

The use of a carbon thermal conduit is considered to exist a peachy opportunity to heat incubator equipment with your own hands. This is a new word in incubator business.

Infrared film

Infrared heating of the incubator is also quite popular recently. This is an innovative material that heats the infinite due to the emission of infrared light. To meliorate the uniformity of heating, the picture show must be concentrated in the center, and along the perimeter of the unit it should be half every bit much. Moreover, the heating element itself does not burn down and does not ignite, which has a very positive effect on the efficiency of the incubation procedure. In addition, it is worth noting that due to this method, information technology is possible to reduce free energy consumption by attaching a reflective substrate of this kind to the picture and equipping the equipment with an automatic temperature regulator.

LED strip

To equip high-quality incubator heating with LEDs, you need to place them in the right mode. An excessively large pace between the LEDs will lead to an uneven distribution of heat over the space, which ways that not all testicles receive the amount of heat necessary for the evolution of the embryos. So, forth the perimeter, the tape should be positioned more rarely than in the center of the unit of measurement.

Notation that this heating method is quite economical, since the energy consumption in this case is quite low. For even greater savings, you should definitely buy a temperature controller that will command the temperature government inside the equipment.

Gas or water

Many craftsmen try to estrus eggs in trays with hot h2o, the steam from which rises. However, this is a very hard way, which is suitable for those cases when the electricity unexpectedly disappears for a long fourth dimension. Units of this kind are as well rarely heated with gas. This is an unsafe method, however, sometimes this method tin save eggs from death.

Thermal Measures

It is clear even to an inexperienced farmer that poor thermal insulation of the incubation equipment will go an obstacle to the effective removal of chicks of any kind of poultry. Therefore, it is imperative to attain the tightness of the unit casing then that the heat emitted past the heating element (infrared film, LEDs, etc.) does non leak out.

In improver, information technology is skilful to have a fan heater or an air mixer. Such products contribute to a uniform distribution of heat throughout the interior of incubation equipment. The video beneath provides detailed instructions on how to organize the correct heating for the incubation equipment with your own easily.

wilkersontrablinever.blogspot.com

Source: https://prokatdrive.ru/en/how-to-choose-the-heating-element-for-an-incubator.html

Belum ada Komentar untuk "what to use as a heat source for an incubator"

Posting Komentar